Overview:

This comprehensive article covers everything about green hydrogen, including its origins, applications, sources, demand, supply, benefits, challenges, along with significant investments and developments in this field.

To begin with, it’s important to clarify that the term “Green Hydrogen” is not related to colors. It is called “green” because the methods involved in its production are considered environmentally friendly and carbon-neutral. We’ll explore this concept in more detail later on.

Hydrogen, being composed of just one electron and one proton at its core, possesses exceptional energy release properties, making it an excellent candidate for use as a combustion fuel. However, naturally occurring free hydrogen is scarce, necessitating a chemical process to extract and convert it into a usable fuel. Various methods can accomplish this, but unfortunately, not all of them are sustainable. This is where the classification based on color comes into play for hydrogen.

Contents:

- What is Green Hydrogen

- How is it Different from Other Hydrogen Fuels

- Key Current Sources of Hydrogen Production

- Why we need Green Hydrogen

- Steps Involved in the Green Hydrogen Making

- Application Areas of Green Hydrogen

- Is it Pocket Friendly

- Key Benefits

- Potential Challenges

- Key Initiatives Taken Across the World for Green Hydrogen

- Major Investments in Green Hydrogen by Top-5 Economies

What is Green Hydrogen:

Green hydrogen is a type of hydrogen produced through a process called electrolysis, wherein water is split into hydrogen and oxygen using renewable electricity derived from non-fossil fuel-based energy sources. As a result, the production of green hydrogen leaves a negligible carbon footprint, making it an environmentally friendly option.

How is it Different from Other Hydrogen Fuels:

Green hydrogen stands apart from other hydrogen fuels, such as grey, pink, or blue hydrogens, as each of them follows a distinct production pathway. For a clearer understanding and comparison, refer to the table below:

| Green Hydrogen | Grey Hydrogen | Pink Hydrogen | Blue Hydrogen | |

| Process Followed | Electrolysis | Steam Reforming | Electrolysis | Steam Reforming with Carbon Capture (85% – 95%) |

| Key Source | Water and Renewable Energy | Methane (CH4) and Coal | Nuclear Energy | Methane (CH4) and Coal |

| Insights | The cleanest method of producing hydrogen fuel involves the process of electrolysis, where water (H2O) is split into hydrogen and oxygen. This process utilizes clean energy sources, resulting in a completely green and environmentally friendly end-to-end production | The most cost-effective process for producing hydrogen fuel, however, involves emissions of greenhouse gases during the production process | The process closely resembles the production of Green Hydrogen, but nuclear energy is employed to create hydrogen fuel. This variant is sometimes referred to as red or purple hydrogen | The hydrogen with a low carbon footprint, however, does not eliminate greenhouse gases entirely; nevertheless, it is an improvement over Grey Hydrogen |

| Black Hydrogen | Yellow Hydrogen | Turquoise Hydrogen | White Hydrogen | |

| Process Followed | Gasification | Electrolysis | Pyrolysis | Fracking |

| Key Source | Coal | Solar Energy | Methane (CH4) | Geological Hydrogen Deposits |

| Insights | The gasification process, involving the treatment of coal, is perhaps the most environmentally polluting method to produce hydrogen fuel. This process generates both hydrogen and CO2 emissions | The process closely resembles Green Hydrogen production, but it exclusively relies on solar energy. The term “yellow” indicates the usage of sunshine as the primary energy source | The process is similar to the Blue Hydrogen method, wherein any carbon generated during the process is converted into a solid form and stored separately. This approach boasts a low carbon footprint | The extraction process involves drilling the earth to release tightly packed hydrogen from the rock bed. However, this method is the least commonly utilized for hydrogen production |

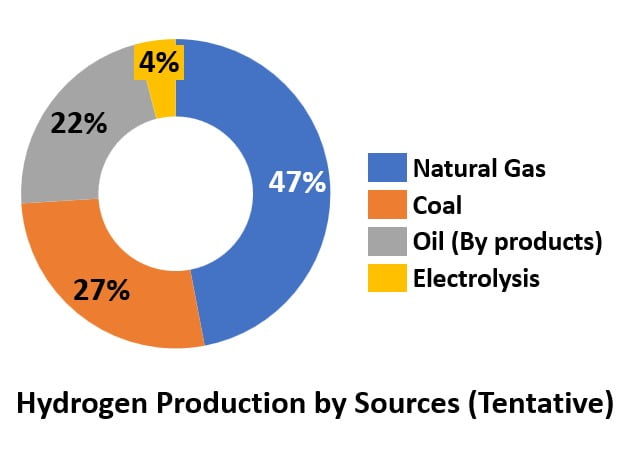

Key Current Sources of Hydrogen Production:

Why we need Green Hydrogen:

In 2021, the global hydrogen demand reached a significant 94 million tonnes (Mt), constituting approximately 2.5% of the world’s final energy consumption, as reported by the International Energy Agency’s (IEA) Global Hydrogen Review 2022. With various government policies and initiatives in place, projections suggest that by 2030, this demand could rise to 115 million tonnes (Mt), driven mainly by traditional industrial applications. However, the production of hydrogen from coal or natural gas (methane, CH4) remains prevalent, resulting in Grey or Black Hydrogen, which carries a substantial carbon footprint and contributes to environmental pollution.

As per an estimation, for every tonne of grey hydrogen produced, approximately 12 tonnes of CO2 are emitted, while black hydrogen emits around 20 tonnes of CO2 per tonne. This leads to an alarming annual CO2 emission contribution of over 1.1 billion tonnes (Bt) from grey and black hydrogen production. To put this into perspective, this emission is equivalent to the combined CO2 emissions of two major industrialized countries, Germany and South Korea.

To alleviate this carbon burden on our planet, the adoption of Green Hydrogen becomes paramount. Transitioning from grey and black hydrogen to green hydrogen can pave the way for a more sustainable future. By doing so, we have the potential to eliminate a carbon footprint equivalent to the combined emissions of Germany and South Korea. Embracing green hydrogen offers a crucial pathway towards reducing greenhouse gas production and working towards a cleaner, more environmentally friendly world.

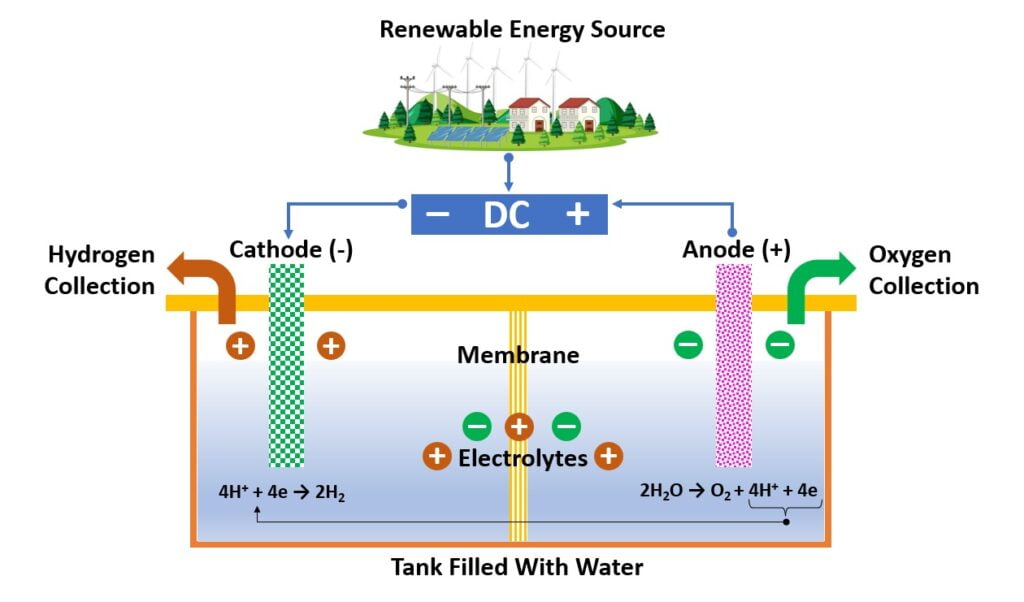

Steps Involved in the Green Hydrogen Making:

Step-1:

The first step in the process is to carefully choose water that contains minerals facilitating the flow of electricity. Unlike distilled water, which lacks these minerals, water with suitable mineral content ensures efficient electrolysis

Step-2:

For the electrolysis to take place, we require two electrodes – the anode and the cathode. These electrodes will be connected to renewable energy sources, providing a direct current (DC) needed for the electrolytic reaction

Step-3:

With the anode and cathode properly positioned, they are immersed in the selected water, and the power supply is activated

Step-4:

As the electricity flows through the water, a fascinating transformation occurs. The anode attracts negatively charged oxygen ions, while the cathode attracts positively charged hydrogen ions

Step-5:

The final step involves a coordinated collection process. The freed oxygen and hydrogen gases, produced as a result of the electrolysis, are carefully gathered separately from both sides of the electrolytic setup. This way, the valuable gases can be captured and utilized effectively for various applications

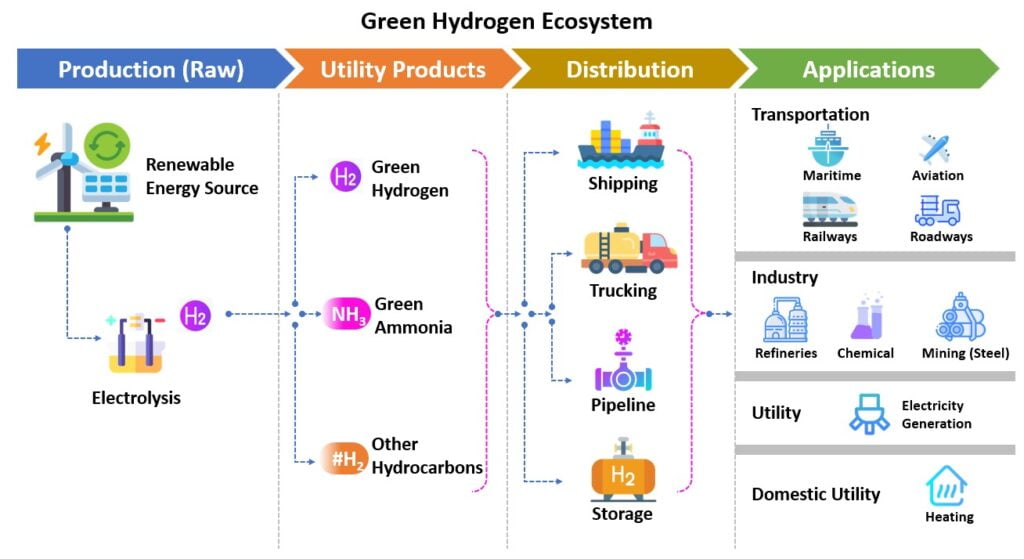

Application Areas of Green Hydrogen:

As of now, three key areas show great promise for the utilization of green hydrogen. These areas are:

Transportation:

The use of green hydrogen as a fuel holds tremendous potential for decarbonizing various modes of transportation, including roadways, marine, and air transport.

Roadways:

In road transportation, green hydrogen can play a crucial role in reducing carbon emissions by powering hydrogen fuel cell vehicles. This technology offers an environmentally friendly alternative to traditional internal combustion engines, helping to curb pollution and combat climate change.

Maritime:

The maritime transport, often reliant on cheap but highly polluting fuels, can benefit significantly from green hydrogen adoption. By utilizing hydrogen as a clean and sustainable fuel source, long-distance vessel transportation can contribute to improving the marine environment and reducing the sector’s environmental impact.

Aviation:

Though the current design of aircraft limits the use of hydrogen for flights traveling over 2,000 km due to its lower energy density compared to fossil jet fuel, ongoing efforts to redesign airframes can address this limitation. By incorporating sufficient hydrogen storage and optimizing aircraft structures, longer flight ranges without compromising passenger capacity can be achieved.

Companies like Airbus have committed to launching zero-emission commercial hydrogen planes by 2035, demonstrating a tangible pathway towards sustainable aviation. Further, hydrogen-powered vehicles are gaining momentum in the automotive industry. Hyundai’s ambitious plan to manufacture 500,000 hydrogen vehicles by 2030 showcases the growing interest in this eco-friendly transportation option. Several countries, including Germany, the US, and China, have already embraced green hydrogen vehicles on their roadways, further advancing the transition to cleaner transportation solutions. Furthermore, France has set its sights on creating a fleet of taxis running on green hydrogen, reflecting a dedicated effort to promote sustainable and zero-emission urban mobility.

Collectively, these developments signify a growing global interest in green hydrogen’s potential to revolutionize the transportation sector, contributing to a cleaner and more sustainable future for our planet.

Industrial Use:

Hydrogen serves as a crucial raw material in various industries, including the chemical, petroleum, and mining sectors.

Chemical Sector:

In the chemical industry, hydrogen plays a pivotal role in the production of ammonia (NH3) and fertilizers, facilitating the manufacturing of essential agricultural products.

Petroleum Sector:

For the petrochemical industry, hydrogen is utilized in petroleum refining processes to remove sulfur from fuels. This results in low-sulfur feedstock, enabling the production of cleaner petroleum-based products such as petrol, diesel, kerosene, and heating oil.

Mining Sector:

In the metal and mining industries, hydrogen serves as a reductant substance, playing a vital role in obtaining steel through reduction processes. However, it is important to note that the use of hydrogen in these industries contributes significantly to the generation of a large carbon footprint. For instance, steel manufacturing alone accounts for approximately 7% of global CO₂ emissions, surpassing the emissions from the entire global aviation sector by two to three times.

To address these carbon-intensive processes, green hydrogen emerges as a promising solution. By employing green hydrogen as a raw material, these industries could achieve emissions-free steel production, making a critical contribution to urgently decarbonize their operations. Such a transformation would represent a significant step toward achieving sustainability goals and reducing the environmental impact of these crucial sectors.

Domestic Energy Utility:

Green hydrogen stands out as an exceptional source of clean domestic energy utilities, offering pollution-free fuel with the unique capability to attain high temperatures that are challenging to achieve through other clean processes. This characteristic makes green hydrogen well-suited for a wide range of domestic applications, including home heating, kitchen cooking, and fulfilling daily electricity requirements.

Moreover, the capacity to store green hydrogen in large volumes over extended periods, similar to strategic oil or natural gas reserves, positions it as an ideal reserve supply of renewable energy sources, providing crucial support to the electricity grid when needed.

Additionally, ongoing sustainable projects in the testing phase aim to revolutionize energy infrastructure by replacing the traditional natural gas pipeline network with a green hydrogen pipeline network. This transformative endeavor reflects the growing interest in leveraging green hydrogen to pave the way for a more sustainable and eco-friendly energy distribution system.

Is it Pocket Friendly:

Currently, green hydrogen production is generally more expensive compared to its counterparts. The involved processes lead to higher costs, placing green hydrogen at the upper end in terms of expense. In contrast, hydrogen produced from fossil fuels offers a cheaper option, typically ranging from USD 0.5 to 1.7 per kg. Introducing Carbon Capture technologies to reduce CO2 emissions during hydrogen production brings the cost to around USD 1 to 2 per kg.

In contrast to these less sustainable black or grey hydrogens, green hydrogen, derived from renewable energy sources, incurs higher costs ranging from USD 3 to 8 per kg, depending on regional supplies and availability. The higher costs of green hydrogen compared to grey or black hydrogens have made it less attractive to end-users. However, with the increasing availability of renewable energy sources, numerous countries are actively aiming to reduce the cost of green hydrogen by USD 1 by the year 2030. These expectations are based on anticipated price drops in electrolysis equipment and renewable energy supplies, which would eventually make green hydrogen nearly cost-competitive with fossil fuels.

As advancements in technology and renewable energy infrastructure continue, the competitiveness of green hydrogen is expected to improve, further incentivizing its adoption as a cleaner and more sustainable energy solution in the future.

Key Benefits:

Sustainability:

Green hydrogen derives its name from its remarkably low carbon footprint and the fact that its combustion produces water as waste. This eco-friendly fuel is produced through the process of electrolysis, where water is split into hydrogen and oxygen using renewable electricity sources. When both the production of green hydrogen and the electricity used in the process come from renewable sources, we can confidently label green hydrogen as entirely carbon neutral.

Offers High Energy per Unit:

Hydrogen gas boasts an impressive energy yield per kilogram, almost equivalent to the energy generated by 2.8 kilograms of gasoline. This remarkable efficiency makes hydrogen a fuel that is nearly three times more effective than gasoline, offering superior value for any application relying on fuel-based energy sources.

Storable:

Much like petroleum gases (LPG or CNG), hydrogen can also be stored in high-pressure compressed tanks for extended periods. This characteristic renders hydrogen portable and easily transportable, making it a versatile and practical option for various applications.

Transportable:

Hydrogen holds the distinction of being the lightest element in the universe. This unique attribute allows for easier handling when stored in compressed tanks, making it more manageable than other portable energy sources, such as lithium batteries. The lightweight nature of hydrogen contributes to its feasibility and convenience in various energy applications.

Resourceful:

Green hydrogen stands out as one of the most versatile elements, as it can be converted into a wide range of applications, including electricity or synthetic gas. This flexibility makes it suitable for diverse purposes, spanning from commercial and industrial uses to various mobility applications. Its adaptability and potential to replace conventional fossil fuels position green hydrogen as a pivotal player in shaping a sustainable and environmentally friendly energy landscape.

Potential Challenges:

High cost:

The production of green hydrogen through electrolysis relies on energy derived from renewable sources, which, unfortunately, tends to be more expensive. Consequently, the cost of obtaining hydrogen becomes higher as well, presenting a challenge to its economic sustainability. To become a viable option for transportation fuel cells, hydrogen must achieve cost-competitiveness with conventional fuels and technologies on a per-mile basis. Striking this balance between affordability and environmental benefits is crucial to accelerate the widespread adoption of hydrogen as a clean and sustainable energy solution.

High Energy Consumption:

Green hydrogen production through electrolysis is indeed an energy-intensive process, typically requiring 55 to 60 units of electricity to produce just 1 kilogram of green hydrogen. In contrast, the production process for grey or black hydrogen does not involve the additional use of electricity for hydrogen generation. This disparity in energy requirements between green and non-green hydrogen production processes highlights one of the challenges faced in scaling up green hydrogen production and making it more economically competitive.

Safety Issues:

While hydrogen is indeed storable, its volatile and flammable nature necessitates the implementation of rigorous safety measures. These precautions are vital to prevent any potential leakage or explosions that could arise from mishandling or accidents. Ensuring the safe storage, transportation, and usage of hydrogen is paramount to maximize its potential as a clean and efficient energy source while minimizing associated risks.

Lack of Infrastructure:

The adoption of green hydrogen for common use is still in its early stages, and as a result, the support infrastructure required for its production, storage, and distribution remains relatively limited. This includes the establishment of essential facilities such as refueling stations for transportation and pipelines for efficient distribution. As the technology and demand for green hydrogen continue to grow, further investments and expansion of infrastructure will be essential to facilitate its widespread integration into everyday applications and make it more accessible to the general public.

Limited Adoption:

In the developing world, the adoption of green hydrogen technology is relatively limited, primarily due to several key factors. One of the major reasons is the lack of awareness and understanding of green hydrogen among the general public. Many people may not be familiar with the concept and potential benefits of green hydrogen, which hinders its widespread acceptance. Additionally, businesses may be hesitant to switch to green hydrogen technology due to the absence of sufficient incentives. Without appropriate incentives and government support, the transition to this eco-friendly alternative may not appear financially attractive to businesses, leading to slower adoption rates.

Key Initiatives Taken Across the World for Green Hydrogen:

Currently, numerous leading economies worldwide have already committed to achieving the International Energy Agency’s net-zero targets. To accomplish this ambitious goal, many of these economies have either implemented sustainable green hydrogen plans or are in the process of finalizing their initiatives. Here is a brief overview of some of the key initiatives taken by these economies:

| Government | Net Zero Target Year | Net zero target (In law) | Hydrogen Strategy Adopted | Hydrogen Strategy Announced |

| Brazil | 2050 | No | – | – |

| Canada | 2050 | Canadian Net-Zero Emissions Accountability Act 2020 | 2020 | – |

| China | 2060 | No | 2022 | – |

| European Commission | 2050 | European Climate Law | 2021 | – |

| France | 2050 | Energy-Climate Act | 2020 | – |

| Germany | 2045 | Federal Climate Protection Act | 2020 | – |

| Italy | 2050 | No | – | 2020 |

| India | 2070 | No | 2023 | – |

| Indonesia | 2060 | No | – | – |

| Iran | – | – | – | – |

| Japan | 2050 | Act on Promotion of Global Warming Countermeasures | 2017 | – |

| Saudi Arabia | 2060 | No | – | – |

| South Korea | 2050 | Carbon Neutrality Act (Framework Act on Carbon Neutrality and Green Growth) | 2019 | – |

| United Kingdom | 2050 | Climate Change Act | 2020 | – |

| United States | 2050 | No | – | 2022 |

Major Investments in Green Hydrogen by Top-5 Economies:

India:

India has launched the National Hydrogen Mission in August 2021, with the goal of establishing the country as a global hub for hydrogen manufacturing and fuel cell technologies. The ambitious mission seeks to produce 5 million metric tonnes of green hydrogen annually by 2030 and achieve net-zero emissions by 2070.

Notable Indian companies have already made significant commitments to invest in green hydrogen projects and infrastructure:

1. Adani Enterprises plans to invest over USD 50 Billion over the period from 2023 to 2033, with the aim of creating a substantial green hydrogen production capacity of 1 million tons per annum before 2030.

2. NTPC, a state-owned enterprise specializing in bulk power generation and distribution, has set its sights on establishing a massive USD 12 Billion (INR 1 Trillion) green hydrogen hub in Andhra Pradesh in 2023.

3. Reliance Industries has ambitious plans to produce hydrogen at a cost of “under USD 1 per 1 kg within a decade” (2023-2033), indicating a strong commitment to scale up green hydrogen production.

4. GAIL, another state-owned enterprise, has taken a significant step by establishing a green hydrogen production unit with a capacity of 4.3 tonnes per day in Guna, Madhya Pradesh, in 2023.

These initiatives reflect India’s determination to position itself as a major player in the global green hydrogen market, accelerating the country’s transition to a more sustainable and low-carbon energy future. With substantial investments and ambitious targets, India is taking decisive steps towards realizing the potential of green hydrogen as a clean and renewable energy source in the coming decades.

China:

1. China Petroleum and Chemical Corporation (Sinopec) has taken a significant step in the green hydrogen sector by launching its inaugural green hydrogen demonstration project in the Inner Mongolia autonomous region. This project involves a substantial investment of USD 828 Million, indicating the company’s commitment to exploring green hydrogen technologies (2023)

2. A notable Chinese public-private consortium is also making a major investment in the green hydrogen space. With a total investment of USD 4.5 Billion, this consortium is set to undertake what it claims will be the largest green hydrogen project, utilizing proton exchange membrane (PEM) electrolyzers. The project, scheduled for 2023, underscores China’s growing interest and commitment to advancing green hydrogen technologies on a large scale

United States:

1. The United States, under the U.S. Department of Energy (DOE), has made a significant commitment to advancing the development of clean hydrogen technologies. The DOE announced the availability of USD 750 Million in funding for research, development, and demonstration efforts aimed at substantially reducing the cost of clean hydrogen. This funding represents the first phase of a larger USD 1.5 Billion allocation from President Biden’s Bipartisan Infrastructure Law, intended to accelerate progress in electrolysis technologies and enhance manufacturing and recycling capabilities (2023)

2. Furthermore, the United States is planning a major investment of USD 4 Billion to establish a green hydrogen plant, which is set to become the largest facility powered by wind and solar energy in the country. This ambitious project reflects the nation’s dedication to leveraging renewable energy sources for green hydrogen production, making significant strides in decarbonizing the energy sector (2023)

Germany:

1. The German government has demonstrated its strong commitment to promoting green hydrogen by allocating more than EUR 4 Billion to a funding scheme aimed at bolstering green hydrogen exports to Germany. This substantial financial support signifies the country’s determination to establish itself as a key player in the global green hydrogen market (2023)

2. The Renewable Energy Agency (AEE) in Germany has been actively fostering the development of green hydrogen production projects. Currently, there are 60 ongoing projects in the country that focus on hydrogen production using renewable energy sources (green hydrogen). Additionally, another 80 projects are in the planning or construction phase, reflecting the nation’s robust efforts to advance the utilization of green hydrogen as a sustainable and clean energy solution (2023)

Japan:

1. Japan is making a substantial commitment to green hydrogen as it plans to invest a staggering USD 107.5 Billion over the next 15 years (2023-2038). This significant investment reflects Japan’s dedication to ensuring a reliable and ample supply of green hydrogen, which will play a pivotal role in the country’s transition to a low-carbon economy.

2. Furthermore, Japan revised its hydrogen strategy by the end of May 2023, with an ambitious target to boost the annual supply of green hydrogen to 12 million tonnes by 2040. This revision signifies Japan’s determination to accelerate the adoption of green hydrogen and underscores its ambition to become a major player in the global green hydrogen market

3 thoughts on “Discover All About Green Hydrogen and Its Importance in Shaping a Sustainable Future”